23.08.2022 MHI

Mitsubishi Power’s Advanced M701F Gas Turbines Begin Commercial Operation at Layyah Gas Turbine Combined Cycle Power Plant Project; Long Term Service Agreement Awarded

- Power project set to be the most efficient (over 60 percent ISO) and advanced F- class power plant in the Middle East

- Long Term Service Agreement also signed today for Layyah project, to support SEWA deliver, high reliability, and efficiency in power supply

Sharjah, U.A.E, August 22, 2022 —Mitsubishi Power, a power solutions brand of Mitsubishi Heavy Industries, Ltd. (MHI), announced today that its two advanced and highly efficient M701F gas turbines have commenced the simple cycle commercial operation at the Layyah power plant in Sharjah in the United Arab Emirates, which is owned and operated by Sharjah Electricity, Water and Gas Authority (SEWA).

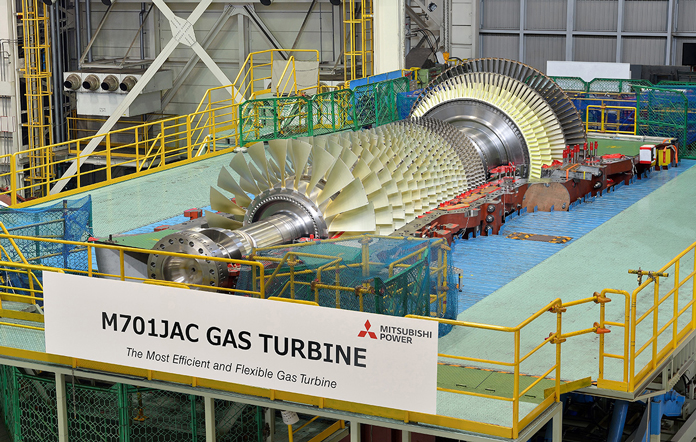

The M701F gas turbines are one of the core equipment of a 1,026MW gas turbine combined-cycle (GTCC) full turnkey project awarded by SEWA, to a consortium of Mitsubishi Power and ELSEWEDY POWER S.A.E. to expand Layyah power plant. The expansion supports Sharjah’s economic development by boosting electricity production and enhancing water production in the Emirate through the adoption of state-of-the-art power generation solutions and facilities.

«We are proud to announce the successful start of operations for the two advanced Mitsubishi Power gas turbines at Layyah combined cycle plant in Sharjah, which is set to become the most efficient and advanced F- class power plant in the Middle East. The Layyah project fulfills the vision of His Highness Sheikh Dr. Sultan Bin Mohammed Al-Qassimi, Member of Supreme Council and Ruler of Sharjah, to meet the Emirate of Sharjah’s electricity demand and SEWA 2030 Roadmap to boost the installed capacity to 4,600 MW and raise the operational efficiency to more than 60%. This will help achieve the Emirate of Sharjah’s vision to meet the growing electricity demand and keep pace with the industrial, commercial and residential development in the Emirate of Sharjah,” said H.E. Saeed Sultan Al Suwaidi, Chairman of Sharjah Electricity, Water and Gas Authority (SEWA).

To further support SEWA in ensuring uninterrupted power supply in the Emirate and enhancing reliability, efficiency, and availability, Mitsubishi Power signed a long-term service agreement (LTSA) with SEWA, encompassing the servicing and maintenance of the units installed at Layyah power plant.

“Mitsubishi Power is a strategic and trusted partner for SEWA for the long-term operation of the new plant. With the company’s global expertise, proven engineering standards, and long-term track record in services across the Middle East, Mitsubishi Power is an ideal partner for the Layyah project. We are delighted to sign the long-term services agreement today and with their extensive experience in services, we look forward to their support in enhancing the efficiency, reliability, quality, and performance of our fleet, ultimately delivering cleaner power and water to the people of Sharjah,” H.E. Al Suwaidi added.

Once completed, Layyah power plant is expected to supply 20 percent of the power for the city of Sharjah.

Under the terms of the agreement, Mitsubishi Power is providing the core equipment, including two gas turbines, one steam turbine, three generators, and two heat recovery steam generators (HRSG). ELSEWEDY POWER is providing the engineering, procurement, construction as well as balance of plant and other equipment at the site.

“Today marks a significant milestone for the Emirate of Sharjah in the UAE as we celebrate the simple cycle commercial operation of Layyah project with our partners SEWA and ELSEWEDY POWER. We are honoured to provide our advanced technologies and services for the landmark Layyah combined cycle plant, which is vital to the continued economic growth of the Emirate of Sharjah in the UAE. We are also thrilled to announce today a long-term service agreement for Layyah plant, which reflects our growing commitment to support SEWA in delivering steady, uninterrupted power and water to households and businesses across Sharjah,” said Khalid Salem, President, Mitsubishi Power Middle East & North Africa.

Through the LTSA, Mitsubishi Power will also implement its award-winning TOMONI® suite of intelligent solutions, to provide real-time adaptive control and actionable knowledge. Mitsubishi Power continues to support the stable supply of power and delivery of efficient power generation technologies in the Middle East and North Africa region and around the world, thereby contributing to the promotion of decarbonization, economic development, and the creation of highly sustainable energy systems on a global scale.

About Mitsubishi Power

Mitsubishi Power is a power solutions brand of Mitsubishi Heavy Industries, Ltd. (MHI). Across more than 30 countries worldwide, Mitsubishi Power designs manufactures and maintains equipment and systems that drive decarbonization and ensure the delivery of reliable power around the world. Among its solutions are a wide range of gas turbines including hydrogen-fueled gas turbines, solid-oxide fuel cells (SOFCs), and air quality control system (AQCS). Committed to providing exemplary service and working with customers to imagine the future of energy, Mitsubishi Power is also spearheading the development of the digital power plant through its suite of AI-enabled TOMONI® solutions.